Our Process

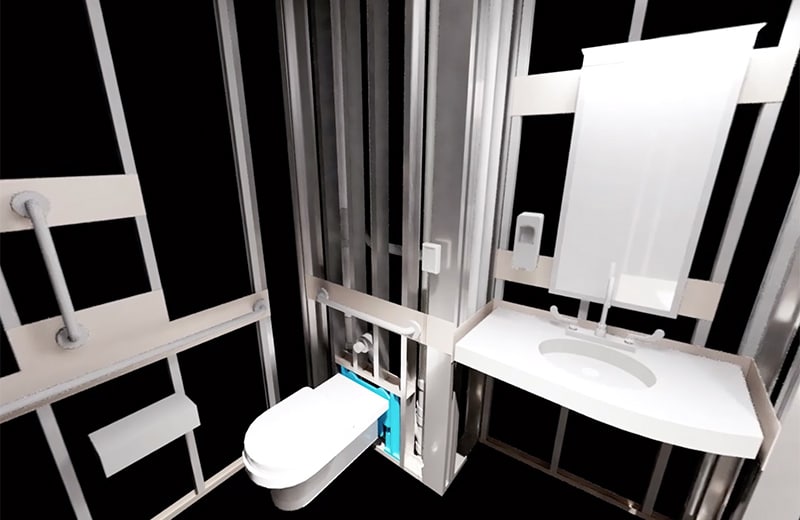

PDM identifies, quantifies, and develops schematic design concepts for each modular construction component. We work directly with the project team to review and refine concepts based on design intent, code requirements, structural/MEP coordination, and end-user requirements. We also work with the project team to develop product and material specifications relevant to each module. To ensure seamless integration, we create 2D and 3D graphical representations of all prefabricated modules to assist in incorporating them into the surrounding architectural environment.

FRAMECAD

PDM is the only contractor in our region that roll-forms our own metal studs and track using the FRAMECAD system. By utilizing FRAMECAD’s Design-Led process, we can rapidly improve production and quality on the job site. FRAMECAD’s technologically advanced manufacturing solutions provide us with the materials, tools, and expertise to facilitate prefabrication efforts.

Rapid Prototyping

Once conceptual layout and dimensions are determined and basic finish selections made, we fabricate a prototype of the module. This is invaluable to advancing the modular construction agenda because it enables the project team to make decisions and provide feedback in a real-time environment. Once the prototype is approved for manufacturing, PDM assembles all prefabricated modules at our 100,000-square-foot modular manufacturing facility in Montgomeryville, Pennsylvania. We provide all union labor and equipment required for fabrication and manage delivery logistics and site coordination for installation.